Solar energy systems have revolutionized the way we harness renewable power, but managing multiple solar panels and their electrical connections can become complex without proper infrastructure. Photovoltaic combiner boxes serve as essential components that streamline solar power management by consolidating multiple DC inputs from solar panel strings into a single output connection. These critical electrical enclosures not only simplify wiring configurations but also enhance system safety, monitoring capabilities, and overall operational efficiency. Understanding how these devices function and their role in modern solar installations helps property owners and installers make informed decisions about their renewable energy investments.

Modern solar installations require sophisticated electrical management systems to handle the complex flow of DC power generated by multiple solar panels. The integration of combiner boxes represents a significant advancement in solar technology, allowing installers to create more organized, safer, and maintainable solar power systems. These devices eliminate the need for numerous individual cable runs from each solar string to the inverter, reducing installation costs and potential failure points throughout the system.

Understanding Solar Power System Architecture

Basic Components of Solar Power Systems

Solar power systems consist of several interconnected components that work together to convert sunlight into usable electricity. Solar panels generate direct current electricity when exposed to sunlight, which must be properly managed and converted before it can power homes or businesses. The electrical flow begins at individual photovoltaic cells within solar panels, which are connected in series to form strings that produce higher voltage outputs suitable for system operation.

Inverters play a crucial role in converting DC electricity from solar panels into alternating current electricity that matches grid specifications. However, between the solar panels and inverters, electrical management devices help organize and protect the power flow. Combiner boxes serve as intermediate collection points where multiple solar strings converge before continuing to the inverter or charge controller systems.

Power Flow Management Challenges

Large solar installations often include dozens or hundreds of solar panels arranged in multiple strings, each generating independent DC outputs that must be properly managed. Without proper organization, these multiple cable runs can create installation challenges, increase material costs, and complicate maintenance procedures. Traditional wiring approaches require individual cables from each string to run directly to inverters or other system components, resulting in complex cable management situations.

Electrical safety concerns also arise when multiple high-voltage DC circuits operate without proper protection and isolation capabilities. Solar installations must comply with strict electrical codes and safety standards, requiring appropriate overcurrent protection, disconnect switches, and grounding systems. Managing these safety requirements across multiple individual circuits becomes increasingly complex as system sizes grow larger.

Combiner Box Functionality and Design

Electrical Consolidation Principles

Combiner boxes operate on the principle of parallel electrical connections, where multiple solar strings connect to individual input terminals within the enclosure. Each input connection maintains electrical isolation while allowing the combined current from all strings to flow through a single output connection. This parallel configuration ensures that if one solar string experiences reduced output or failure, the remaining strings continue operating normally without affecting overall system performance.

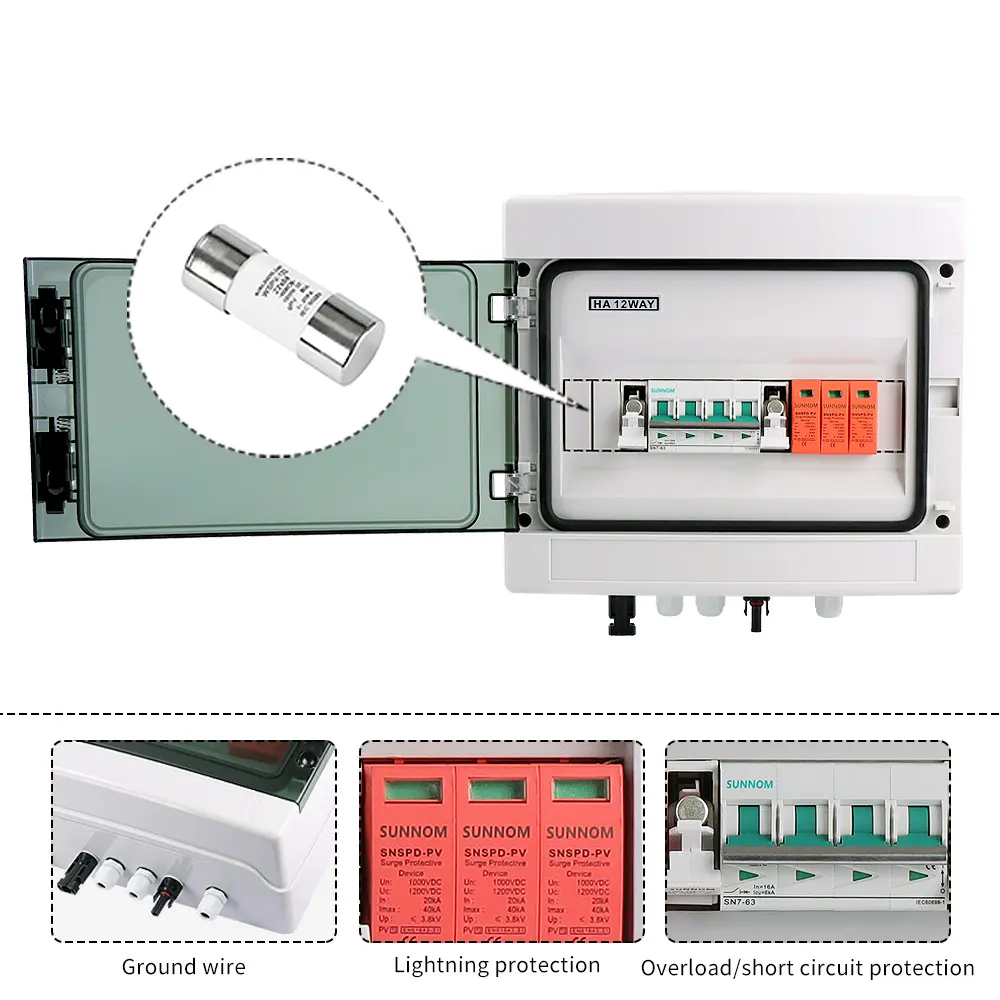

The internal design of photovoltaic combiner boxes includes individual fused connections for each input string, providing overcurrent protection and isolation capabilities. These fuses protect against potential short circuits, ground faults, or other electrical anomalies that could damage equipment or create safety hazards. The fused inputs also allow installers to disconnect individual strings for maintenance without shutting down the entire solar array.

Protection and Monitoring Features

Modern combiner boxes incorporate advanced protection features that enhance system reliability and safety beyond basic electrical consolidation. Ground fault detection circuits monitor for potential electrical leakage that could indicate damaged cables or compromised insulation. These protection systems automatically disconnect affected circuits when anomalies are detected, preventing potential fire hazards or electrical shock risks.

Many combiner boxes also include monitoring capabilities that provide real-time data about individual string performance, current levels, and system status. Digital displays or communication interfaces allow installers and system owners to track performance trends, identify underperforming strings, and schedule preventive maintenance activities. These monitoring features significantly improve system management capabilities compared to traditional wiring approaches that provide limited visibility into individual string performance.

Installation and Wiring Simplification

Reduced Cable Requirements

Installing combiner boxes dramatically reduces the total cable length required in solar installations by eliminating individual home runs from each solar string to system inverters. Instead of running separate cables across potentially long distances from rooftop arrays to ground-mounted inverters, installers can locate combiner boxes strategically near solar arrays and run a single consolidated cable to downstream equipment. This approach reduces material costs, installation labor, and potential voltage drop issues associated with long cable runs.

The consolidation of wiring also simplifies cable management and reduces the physical space required for electrical connections. Rather than managing numerous individual cables at inverter locations, installers work with fewer, larger conductors that carry the combined output from multiple solar strings. This streamlined approach improves installation aesthetics and makes future maintenance activities more manageable.

Standardized Connection Procedures

Combiner boxes provide standardized connection points that streamline installation procedures and reduce the potential for wiring errors. Each input terminal is clearly labeled and designed for specific conductor sizes, ensuring consistent connections across all solar strings. The standardized approach reduces installation time and helps ensure reliable long-term connections that maintain system performance over decades of operation.

Installation procedures become more systematic when using combiner boxes, as installers can work methodically through each input connection before proceeding to output wiring. This organized approach reduces the likelihood of missed connections or improper wiring that could compromise system performance or safety. The clear organization also facilitates inspection procedures by electrical authorities who must verify compliance with local electrical codes.

Safety Enhancement and Code Compliance

Overcurrent Protection Integration

Combiner boxes incorporate individual overcurrent protection devices for each solar string input, providing comprehensive protection against electrical faults that could damage equipment or create safety hazards. These protection devices are sized specifically for solar applications and designed to handle the unique characteristics of photovoltaic power generation. The integrated protection eliminates the need for separate fusing or circuit breaker installations, simplifying overall system design while ensuring comprehensive safety coverage.

The overcurrent protection features help solar installations comply with National Electrical Code requirements and local electrical standards that mandate appropriate protection for all electrical circuits. By integrating these protection devices within the combiner box enclosure, installers can ensure consistent protection levels across all solar strings while maintaining organized, code-compliant installations that pass electrical inspections reliably.

Disconnect and Isolation Capabilities

Modern combiner boxes include disconnect switches that allow maintenance personnel to safely isolate solar strings or the entire combiner output during service activities. These disconnect capabilities are essential for compliance with electrical safety standards and enable safe maintenance procedures on solar installations. The ability to disconnect individual strings also allows for targeted troubleshooting and repair activities without affecting the operation of healthy solar strings.

Proper labeling and lockout/tagout procedures ensure that maintenance activities can be performed safely according to electrical safety standards. The integrated disconnect capabilities eliminate the need for separate disconnect switches and associated wiring, simplifying system design while maintaining essential safety features required by electrical codes and safety regulations.

Performance Monitoring and Maintenance Benefits

Individual String Monitoring

Advanced combiner boxes provide detailed monitoring capabilities that allow system owners and maintenance personnel to track individual string performance and identify potential issues before they impact overall system output. Current measurement devices within each input circuit provide real-time data about string performance, enabling proactive maintenance approaches that maximize system availability and energy production throughout the system lifecycle.

The monitoring data helps identify gradual performance degradation, partial shading issues, or equipment failures that might otherwise go unnoticed until they significantly impact system output. Early detection of these issues allows for timely maintenance interventions that restore optimal performance and prevent minor problems from developing into major system failures that require expensive repairs or extended downtime.

Simplified Troubleshooting Procedures

Combiner boxes centralize connection points and monitoring capabilities, making troubleshooting procedures more efficient and systematic. Maintenance personnel can quickly assess the performance of all solar strings from a single location, identifying problematic circuits without extensive testing procedures across distributed connection points. The organized approach reduces diagnostic time and helps ensure that maintenance activities address root causes rather than symptoms of underlying issues.

The ability to isolate individual strings during troubleshooting activities allows maintenance personnel to test and repair specific circuits while maintaining power production from healthy portions of the solar array. This capability minimizes revenue loss during maintenance activities and ensures that routine maintenance procedures do not unnecessarily impact system performance or energy production schedules.

Cost-Effectiveness and Return on Investment

Reduced Installation Costs

While combiner boxes represent an additional component cost in solar installations, they typically provide overall cost savings through reduced cable requirements, simplified installation procedures, and decreased labor costs. The consolidation of wiring reduces the total conductor length needed, which becomes particularly significant in large installations where cable costs represent a substantial portion of total project expenses. The simplified installation procedures also reduce labor requirements, allowing installation crews to complete projects more efficiently.

Long-term cost benefits include reduced maintenance requirements and improved system reliability that minimizes repair costs over the system lifecycle. The organized wiring approach facilitated by combiner boxes makes maintenance activities more efficient, reducing service costs and system downtime. The integrated protection features also help prevent equipment damage that could result in expensive repair or replacement costs throughout the system operating life.

Enhanced System Value

Properties with well-designed solar installations that incorporate professional-grade components like combiner boxes typically maintain higher resale values compared to installations with basic wiring approaches. The professional appearance and enhanced safety features demonstrate quality installation practices that appeal to potential buyers who value renewable energy systems. The monitoring capabilities also provide ongoing value by enabling optimization of energy production and early detection of maintenance needs.

Insurance considerations may also favor installations with comprehensive safety features and professional-grade components, potentially resulting in lower premiums or better coverage terms. The documented safety features and code compliance facilitated by combiner boxes help demonstrate the quality and reliability of solar installations to insurance providers who evaluate risk factors associated with renewable energy systems.

FAQ

What size combiner box do I need for my solar installation

The appropriate combiner box size depends on the number of solar strings in your installation and the current capacity of each string. Most residential installations with 8-12 strings can use standard 8-position or 12-position combiner boxes, while larger commercial installations may require custom configurations. Calculate the total current from all strings and ensure the combiner box output capacity exceeds this value by at least 25% for safety margins. Consult with your solar installer to determine the optimal configuration for your specific system requirements and local electrical code compliance.

Can I install a combiner box myself or do I need a professional electrician

Combiner box installation requires electrical knowledge and must comply with local electrical codes and permit requirements. Most jurisdictions require licensed electricians to perform this type of electrical work, and professional installation is strongly recommended to ensure safety and code compliance. The installation involves high-voltage DC circuits that can be dangerous if handled improperly. Professional installers also understand proper grounding, protection coordination, and inspection requirements that ensure reliable long-term operation and compliance with warranty terms.

How often should combiner boxes be inspected and maintained

Annual inspections are recommended for combiner boxes to verify proper operation of protection devices, check connection tightness, and review monitoring data for performance trends. Visual inspections should look for signs of overheating, corrosion, or physical damage to the enclosure. The monitoring data should be reviewed regularly to identify gradual performance changes that might indicate developing issues. Professional maintenance services can perform comprehensive testing of protection devices and electrical connections to ensure continued safe operation throughout the system lifecycle.

What happens if one solar string fails when connected through a combiner box

Combiner boxes are designed with parallel connections that allow individual strings to fail without affecting the operation of other strings in the system. If one string experiences reduced output or complete failure, the remaining strings continue operating normally while the affected string can be isolated using its individual fuse or disconnect switch. This design provides excellent system reliability and allows for targeted maintenance on problematic strings while maintaining power production from healthy portions of the solar array. The monitoring capabilities help identify failed strings quickly so repairs can be scheduled efficiently.