Solar photovoltaic systems represent a significant investment in renewable energy infrastructure, requiring comprehensive protection strategies to ensure long-term operational stability and maximum return on investment. Among the critical components safeguarding these systems, DC surge protectors serve as the primary defense against voltage spikes and electrical transients that can cause catastrophic damage to sensitive electronic equipment. Proper maintenance of these protective devices is essential for preserving system integrity and preventing costly downtime or equipment replacement.

The complexity of modern photovoltaic installations demands a systematic approach to surge protection maintenance that goes beyond basic visual inspections. Environmental factors, system configuration changes, and evolving electrical codes all influence the performance requirements and maintenance protocols for DC surge protectors. Understanding these interconnected elements enables facility managers and technicians to develop comprehensive maintenance strategies that extend equipment lifespan while maintaining optimal system performance.

Understanding DC Surge Protection Fundamentals

Operating Principles and System Integration

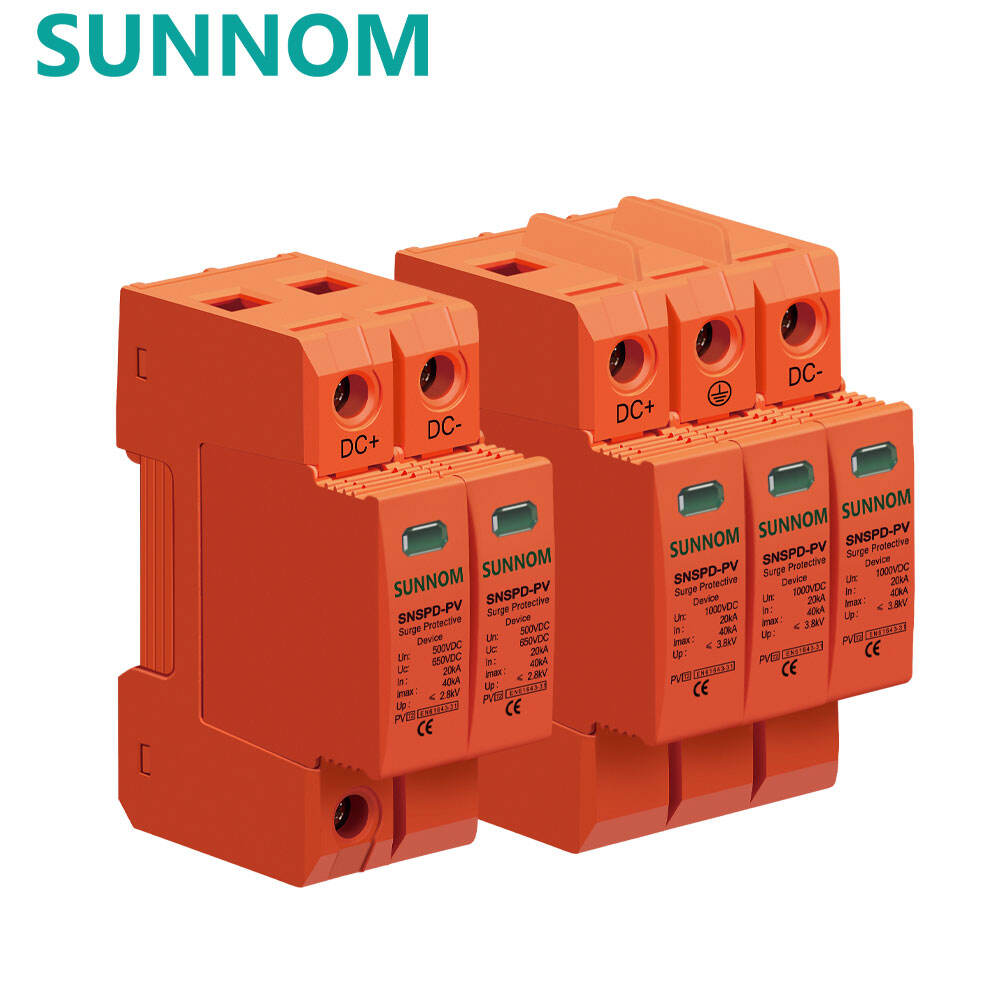

DC surge protectors function as voltage-sensitive switches that divert excessive electrical energy away from critical system components during transient events. These devices utilize various technologies including metal oxide varistors, gas discharge tubes, and silicon avalanche diodes to achieve rapid response times measured in nanoseconds. The integration of these protective elements within photovoltaic systems requires careful consideration of voltage ratings, current handling capacity, and coordination with other protective devices throughout the electrical distribution network.

The effectiveness of surge protection depends heavily on proper grounding systems and the strategic placement of protective devices at key system interfaces. DC surge protectors must be installed at locations where different system components interconnect, including combiner boxes, inverter inputs, and monitoring equipment connections. This distributed protection approach ensures that transient voltages are intercepted before reaching sensitive electronic components that could suffer permanent damage from even brief exposure to excessive voltage levels.

Environmental Impact on Performance

Environmental conditions significantly influence the performance characteristics and maintenance requirements of DC surge protectors in photovoltaic applications. Temperature fluctuations affect the response characteristics of protective elements, while humidity and corrosive atmospheres can accelerate component degradation and compromise protective performance. Solar installations in coastal environments face additional challenges from salt spray exposure, which can cause accelerated corrosion of metallic components and degradation of insulation materials.

Ultraviolet radiation exposure represents another critical environmental factor that affects surge protector enclosures and external components. Extended exposure to high-intensity solar radiation can cause polymer materials to become brittle and lose their protective properties over time. Understanding these environmental influences enables maintenance personnel to adjust inspection frequencies and replacement schedules based on actual operating conditions rather than generic manufacturer recommendations.

Comprehensive Inspection Protocols

Visual Assessment Techniques

Regular visual inspections form the foundation of effective DC surge protector maintenance programs, providing early warning signs of potential component failures before they compromise system protection. Trained technicians should examine protective device enclosures for signs of physical damage, including cracks, discoloration, or deformation that might indicate exposure to excessive temperatures or mechanical stress. Particular attention should be paid to connection points where loose or corroded terminals can create high-resistance pathways that generate heat and reduce protective effectiveness.

The inspection process should include detailed documentation of component condition using standardized assessment criteria and photographic records to track degradation trends over time. Status indicators on surge protective devices provide valuable information about device condition, with many modern units incorporating visual or electronic indicators that signal when replacement is necessary. However, these indicators should supplement rather than replace comprehensive visual inspections, as they may not detect all potential failure modes or degradation mechanisms.

Electrical Testing Procedures

Electrical testing of DC surge protectors requires specialized equipment and procedures to verify proper operation without damaging the protective components. Insulation resistance testing using appropriate test voltages confirms that protective elements have not degraded to the point where they conduct current under normal operating conditions. These tests must be performed with the surge protectors disconnected from the protected circuits to prevent damage to sensitive electronic equipment during the testing process.

Leakage current measurements provide additional insight into surge protector condition by detecting gradual degradation of protective elements before complete failure occurs. Trending these measurements over time enables maintenance personnel to identify devices that are approaching end-of-life conditions and schedule replacements during planned maintenance windows rather than waiting for emergency failures. Ground resistance testing ensures that the protective devices have adequate grounding connections to effectively divert surge currents away from protected equipment.

Preventive Maintenance Strategies

Scheduled Replacement Programs

Implementing proactive replacement programs for DC surge protectors helps prevent system failures caused by end-of-life component degradation. These programs should consider both calendar-based replacement schedules and condition-based replacement criteria that account for actual operating stress levels and environmental exposure. Manufacturing specifications provide baseline guidance for expected service life, but actual replacement intervals may need adjustment based on local environmental conditions and system operating characteristics.

Documentation of surge events and their magnitude provides valuable data for optimizing replacement schedules by identifying devices that have experienced significant stress levels. Modern monitoring systems can record transient event data that helps quantify the cumulative stress experienced by protective devices over their service life. This information enables more accurate prediction of remaining useful life and helps justify the cost of proactive replacement programs through reduced emergency maintenance expenses.

Environmental Protection Measures

Protecting DC surge protectors from environmental degradation extends their service life and maintains optimal performance characteristics throughout their operational period. Proper enclosure selection and sealing prevent moisture ingress that can cause corrosion and insulation degradation, while adequate ventilation prevents excessive temperature buildup that accelerates component aging. UV-resistant materials and coatings protect external components from solar radiation damage in outdoor installations.

Regular cleaning of surge protector enclosures removes accumulated debris and contaminants that can interfere with proper operation or create pathways for moisture ingress. Particular attention should be paid to ventilation openings and drainage provisions that prevent water accumulation within enclosures. Sealing compound inspection and renewal ensures continued protection against environmental intrusion while maintaining necessary pressure relief capabilities for internal arc events.

Troubleshooting Common Issues

Performance Degradation Indicators

Recognizing early warning signs of DC surge protector degradation enables timely intervention before complete failure occurs. Increased leakage current measurements often indicate that protective elements are beginning to degrade and may not provide adequate protection during future surge events. Temperature rise at connection points suggests developing high-resistance connections that can lead to overheating and potential fire hazards if not corrected promptly.

System monitoring data can reveal subtle changes in protective device behavior that precede obvious failure symptoms. Voltage measurements across surge protectors during normal operation should remain within specified limits, with any significant deviation indicating potential internal component degradation. Correlation of monitoring data with environmental conditions helps identify external factors contributing to accelerated degradation and guides corrective actions to extend device life.

Emergency Response Procedures

Developing comprehensive emergency response procedures for surge protector failures ensures rapid restoration of system protection while minimizing exposure to additional damage. These procedures should include rapid assessment protocols to determine the extent of damage and identify temporary protective measures that can be implemented while permanent repairs are arranged. Emergency spare parts inventory should include commonly replaced components and complete surge protector assemblies to minimize system downtime.

Coordination with system operators and monitoring personnel ensures that surge protector failures are detected quickly and appropriate response actions are initiated. Clear communication protocols should be established to notify relevant personnel of protective system status changes and coordinate maintenance activities that may affect system operation. Post-incident analysis procedures help identify root causes of failures and guide improvements to prevent similar occurrences in the future.

Integration with System Monitoring

Real-Time Status Monitoring

Modern photovoltaic systems increasingly incorporate real-time monitoring capabilities that can provide continuous surveillance of DC surge protector status and performance. These monitoring systems can detect changes in protective device characteristics that indicate developing problems, enabling proactive maintenance actions before failures occur. Integration with plant-wide monitoring systems provides centralized visibility into protective system status across multiple locations and equipment types.

Automated alert systems can notify maintenance personnel immediately when surge protector parameters exceed acceptable limits or when protective devices indicate end-of-life conditions. These capabilities are particularly valuable for remote installations where manual inspection frequency may be limited by accessibility or cost considerations. Data logging functions provide historical records that support trend analysis and optimization of maintenance schedules based on actual operating experience.

Performance Analytics and Optimization

Advanced analytics capabilities enable deeper insights into DC surge protector performance patterns and help identify opportunities for system optimization. Machine learning algorithms can process large datasets to identify subtle correlations between environmental conditions, system operating parameters, and protective device degradation rates. This information supports development of predictive maintenance models that optimize replacement timing and reduce overall maintenance costs.

Comparative analysis of surge protector performance across different system locations and configurations helps identify best practices and design improvements that enhance overall system reliability. Performance benchmarking against industry standards and manufacturer specifications ensures that maintenance programs meet or exceed recommended practices while adapting to specific operating requirements and constraints.

FAQ

How often should DC surge protectors be inspected in photovoltaic systems

DC surge protectors should undergo visual inspection quarterly, with comprehensive electrical testing performed annually or after significant weather events. However, inspection frequency may need adjustment based on environmental conditions, with installations in harsh environments requiring more frequent attention. Systems with integrated monitoring capabilities may extend intervals between manual inspections while maintaining continuous automated surveillance of critical parameters.

What are the key warning signs that indicate DC surge protector replacement is needed

Primary indicators include visual damage to enclosures or terminals, activation of end-of-life indicators, increased leakage current measurements, and elevated operating temperatures. Additionally, any surge protector that has experienced multiple large transient events should be evaluated for replacement even if no obvious damage is visible, as cumulative stress can reduce protective capability without obvious external symptoms.

Can DC surge protectors be tested while the photovoltaic system remains operational

Limited testing can be performed on energized systems, including visual inspections and thermal imaging, but comprehensive electrical testing requires disconnection from protected circuits. Most electrical tests involve applying voltages that could damage sensitive equipment if performed on connected systems. Always follow manufacturer guidelines and applicable safety standards when planning testing procedures for energized installations.

What environmental factors most significantly affect DC surge protector lifespan

Temperature extremes, humidity levels, UV radiation exposure, and atmospheric pollutants are the primary environmental factors affecting surge protector longevity. Coastal installations face additional challenges from salt spray corrosion, while desert environments present extreme temperature cycling and dust accumulation issues. Proper enclosure selection and environmental protection measures can significantly extend device life in challenging conditions.

Table of Contents

- Understanding DC Surge Protection Fundamentals

- Comprehensive Inspection Protocols

- Preventive Maintenance Strategies

- Troubleshooting Common Issues

- Integration with System Monitoring

-

FAQ

- How often should DC surge protectors be inspected in photovoltaic systems

- What are the key warning signs that indicate DC surge protector replacement is needed

- Can DC surge protectors be tested while the photovoltaic system remains operational

- What environmental factors most significantly affect DC surge protector lifespan