crimping solar connectors

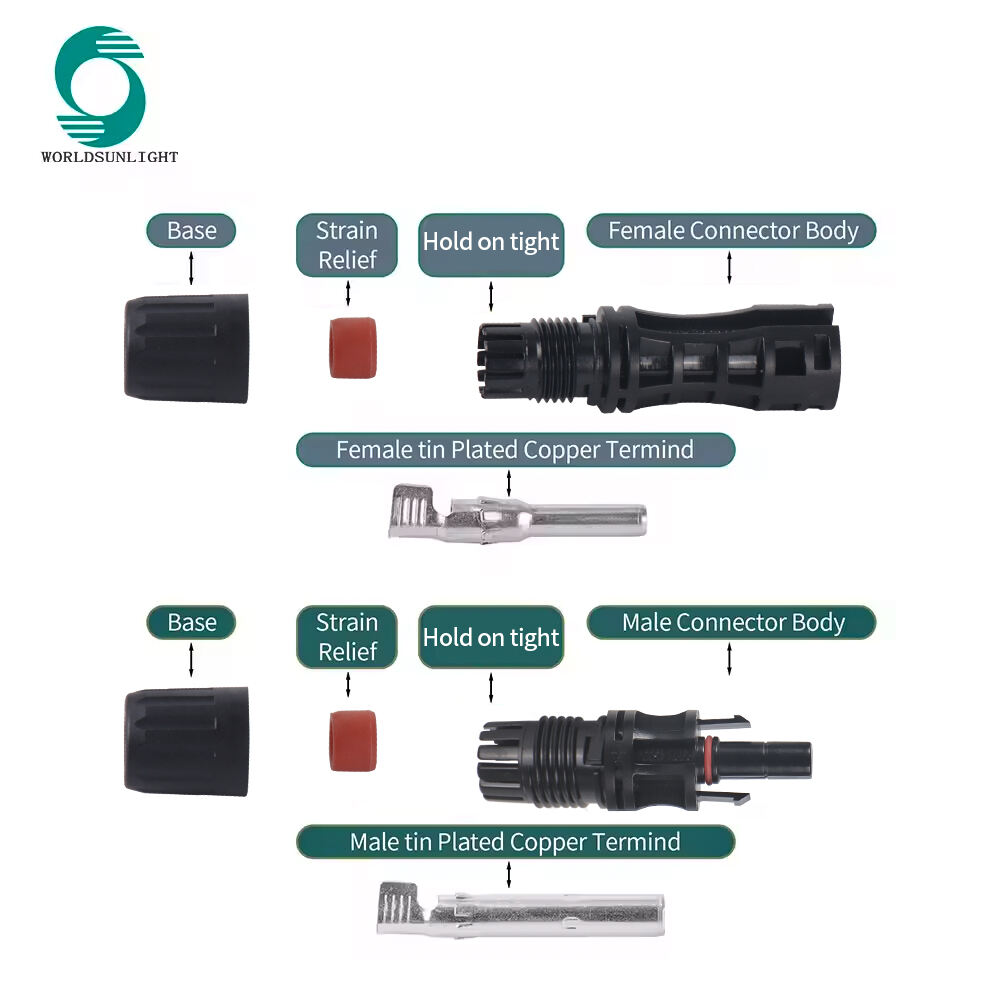

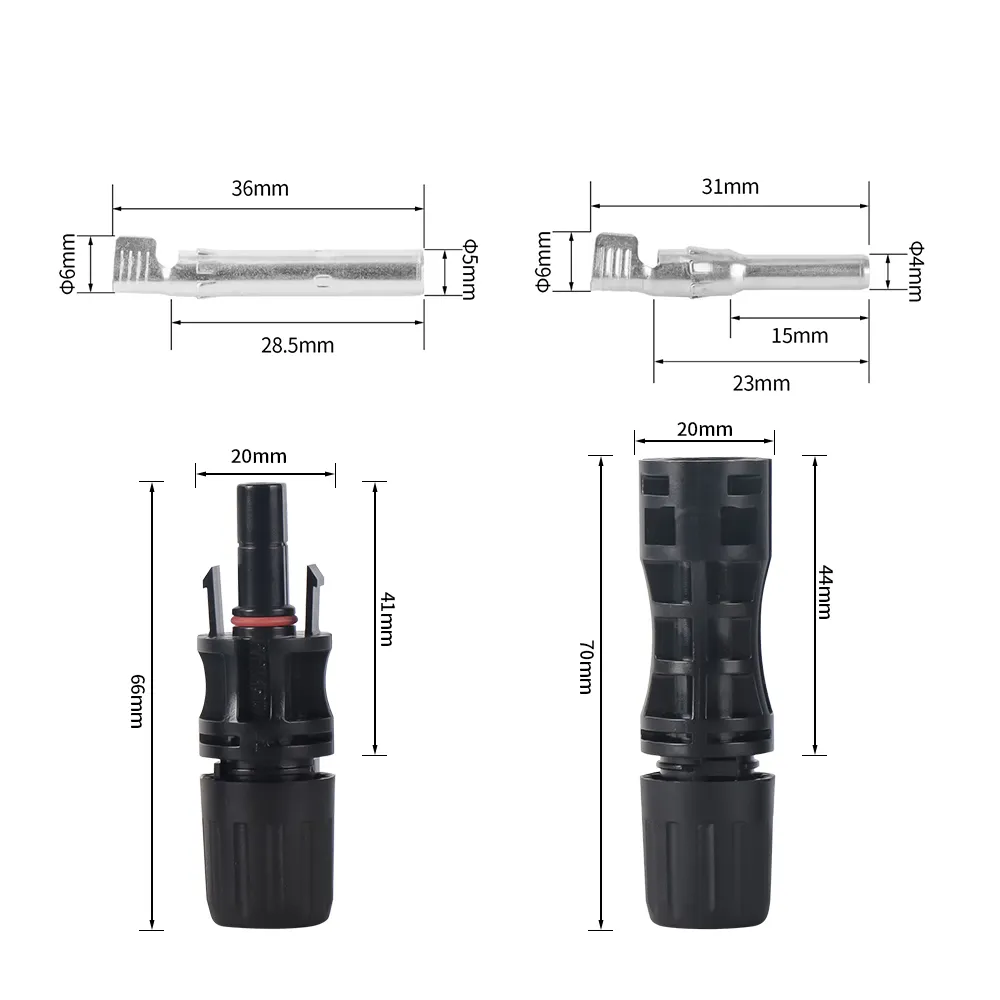

Crimping solar connectors are essential components in photovoltaic systems, designed to establish secure and reliable electrical connections between solar panels and other system components. These specialized connectors utilize a mechanical crimping process that creates a permanent, weather-resistant bond between the connector and the solar cable. The crimping process involves compressing the connector's metal sleeve around the cable's conductor, ensuring optimal electrical conductivity and mechanical strength. Modern crimping solar connectors feature advanced design elements, including UV-resistant materials, IP67 or higher waterproof ratings, and compatibility with industry-standard cable sizes. They typically incorporate safety features such as touch-proof designs and locking mechanisms to prevent accidental disconnection. The connectors are engineered to maintain consistent performance across extreme temperature ranges, often from -40°C to +85°C, making them suitable for diverse environmental conditions. These connectors play a crucial role in maintaining system efficiency by minimizing power losses at connection points and ensuring long-term reliability of the solar installation. Professional-grade crimping tools are used to achieve precise compression, resulting in connections that meet strict industry standards for electrical resistance and pull-out strength.