Modern energy systems face unprecedented challenges from electrical surges, particularly in direct current applications where traditional protection methods often fall short. As renewable energy installations and industrial DC applications continue to expand globally, the critical importance of specialized DC surge protectors becomes increasingly evident. These advanced protective devices serve as the first line of defense against voltage spikes that can devastate sensitive equipment and cause costly downtime in photovoltaic systems, battery storage installations, and industrial DC networks.

The electrical infrastructure supporting today's energy systems operates under increasingly complex conditions, where lightning strikes, switching operations, and grid disturbances generate powerful transient voltages. Unlike alternating current systems that benefit from natural zero-crossing points, direct current systems maintain continuous voltage levels that make surge protection more challenging and critical. Professional engineers and system designers recognize that implementing robust DC surge protectors represents a fundamental requirement rather than an optional enhancement in modern electrical installations.

Understanding DC Surge Protection Technology

Fundamental Principles of DC Surge Suppression

Direct current surge protection operates on sophisticated principles that differ significantly from traditional AC protection methods. The continuous nature of DC voltage requires specialized components capable of handling sustained current flow while responding rapidly to transient overvoltage conditions. Metal oxide varistors, gas discharge tubes, and silicon avalanche diodes work in coordinated configurations to provide multi-stage protection that can handle both fast-rising transients and sustained overvoltage events.

The clamping characteristics of quality DC surge protectors must maintain precise voltage thresholds to protect sensitive electronic components while allowing normal operational voltages to pass unimpeded. Advanced designs incorporate thermal protection mechanisms and fail-safe features that prevent catastrophic failure modes, ensuring that protection devices themselves do not become sources of system vulnerability. These sophisticated protection schemes require careful coordination with system grounding and bonding practices to achieve optimal performance.

Advanced Protection Circuit Configurations

Modern DC surge protectors employ cascaded protection architectures that provide multiple layers of defense against various surge characteristics. Primary protection stages utilize high-energy absorption components designed to handle direct lightning strikes and major switching transients, while secondary stages provide precise voltage clamping for sensitive electronic loads. This multi-stage approach ensures that each protection element operates within its optimal performance range while providing comprehensive coverage across the entire threat spectrum.

The integration of monitoring and diagnostic capabilities in contemporary surge protection devices enables real-time assessment of protection system health and performance. Status indication systems provide immediate feedback regarding protection device condition, allowing maintenance personnel to identify degraded components before they compromise system protection. Remote monitoring capabilities further enhance system reliability by enabling continuous surveillance of protection system status across distributed installations.

Critical Applications in Renewable Energy Systems

Photovoltaic System Protection Requirements

Solar photovoltaic installations present unique challenges for surge protection due to their distributed nature, elevated mounting positions, and exposure to environmental extremes. DC surge protectors in PV systems must handle the specific characteristics of solar-generated electrical energy while protecting against both atmospheric and switching-induced transients. The long DC cable runs typical in solar installations act as antennas for lightning-induced surges, making robust protection essential for system longevity and performance.

The economic impact of surge-related damage in commercial solar installations can be substantial, affecting not only equipment replacement costs but also lost energy production during repair periods. Professional-grade DC surge protectors designed specifically for photovoltaic applications incorporate features such as high voltage ratings, low leakage currents, and robust construction materials suitable for outdoor environments and extended operational lifespans.

Energy Storage System Integration

Battery energy storage systems represent one of the fastest-growing applications for DC surge protection technology, driven by the proliferation of grid-scale storage projects and residential energy storage installations. These systems combine high-energy battery banks with sophisticated power electronics that require precise protection against voltage transients. The bidirectional power flow characteristics of energy storage systems create unique protection challenges that demand specialized surge protection solutions.

The integration of DC surge protectors in energy storage applications must consider the specific characteristics of different battery technologies and their associated charging and discharging profiles. Lithium-ion systems, in particular, require protection devices that can handle the rapid current changes associated with fast charging and high-power discharge operations while maintaining precise voltage regulation to prevent battery management system interference.

Industrial DC System Protection Strategies

Manufacturing and Process Control Applications

Industrial manufacturing facilities increasingly rely on DC-powered systems for precision control applications, variable frequency drives, and automated production equipment. These systems operate in electrically noisy environments where switching operations, motor starts, and other industrial processes generate continuous sources of electrical transients. DC surge protectors in industrial applications must provide reliable protection while maintaining the high availability requirements of continuous production operations.

The selection of appropriate protection devices for industrial DC systems requires careful analysis of system architecture, load characteristics, and environmental conditions. Harsh industrial environments subject protection equipment to temperature extremes, vibration, electromagnetic interference, and contamination that can degrade performance over time. Rugged protection devices designed for industrial service incorporate enhanced environmental protection and extended operational temperature ranges to ensure reliable long-term performance.

Transportation and Infrastructure Systems

Modern transportation systems, including electric rail networks, electric vehicle charging infrastructure, and marine electrical systems, rely heavily on DC power distribution that requires sophisticated surge protection. These applications often involve high-power systems operating in exposed environments where lightning exposure and electrical noise are significant concerns. The critical nature of transportation infrastructure demands protection systems with proven reliability and rapid response characteristics.

Electric vehicle charging stations present particularly challenging protection requirements due to their outdoor installation locations, high-power operation, and connection to both utility distribution systems and vehicle electrical systems. DC surge protectors for EV charging applications must coordinate with both AC input protection and DC output protection to provide comprehensive system protection while maintaining the fast charging capabilities demanded by modern electric vehicles.

Installation and Maintenance Best Practices

Proper Installation Techniques

The effectiveness of DC surge protectors depends critically on proper installation practices that ensure optimal protection performance and system coordination. Installation procedures must address conductor routing, grounding connections, and protection device placement to minimize lead lengths and inductance that can compromise surge protection effectiveness. Professional installation requires understanding of surge current paths and the importance of creating low-impedance connections between protection devices and protected equipment.

Coordination between different levels of protection devices requires careful attention to timing and voltage coordination to prevent improper operation during surge events. The installation of monitoring and indication systems enables ongoing verification of protection system status and provides early warning of protection device degradation or failure. Proper documentation of protection system configuration and settings facilitates future maintenance activities and system modifications.

Ongoing Maintenance and Testing Requirements

Regular maintenance and testing of DC surge protectors ensures continued protection effectiveness throughout the operational life of electrical systems. Maintenance programs should include visual inspection of protection devices, verification of status indication systems, and periodic testing of protection device parameters. The development of maintenance schedules based on manufacturer recommendations, environmental conditions, and system criticality helps optimize protection system reliability while minimizing maintenance costs.

Advanced diagnostic techniques, including insulation resistance testing, thermal imaging, and partial discharge analysis, can identify degraded protection components before they fail completely. The implementation of predictive maintenance strategies based on condition monitoring data enables optimization of maintenance intervals and reduction of unexpected protection system failures that could compromise system protection.

Future Trends in DC Surge Protection Technology

Smart Protection Systems and IoT Integration

The integration of smart technology and Internet of Things connectivity in DC surge protectors represents a significant advancement in protection system capabilities. Smart protection devices incorporate advanced monitoring, communication, and diagnostic features that enable real-time assessment of protection system performance and predictive maintenance capabilities. These systems can automatically report protection events, device status, and performance trends to central monitoring systems for analysis and response.

Machine learning algorithms applied to surge protection data can identify patterns and trends that indicate developing problems or optimization opportunities. The ability to correlate surge protection events with weather data, system operating conditions, and equipment performance provides valuable insights for improving overall system reliability and protection effectiveness. Cloud-based monitoring platforms enable remote monitoring and management of protection systems across distributed installations.

Advanced Materials and Component Technologies

Ongoing research and development in surge protection materials and components continues to improve the performance and reliability of DC surge protectors. Advanced semiconductor materials, including silicon carbide and gallium nitride devices, offer superior performance characteristics for high-voltage and high-frequency surge protection applications. These materials enable the development of more compact protection devices with improved response times and energy handling capabilities.

Nanotechnology applications in surge protection components promise further improvements in protection device performance and longevity. Advanced manufacturing techniques enable the production of protection components with more precise characteristics and improved reliability under extreme operating conditions. The development of self-healing protection materials and adaptive protection systems represents the next generation of surge protection technology that will further enhance system protection capabilities.

FAQ

What voltage levels do DC surge protectors typically handle?

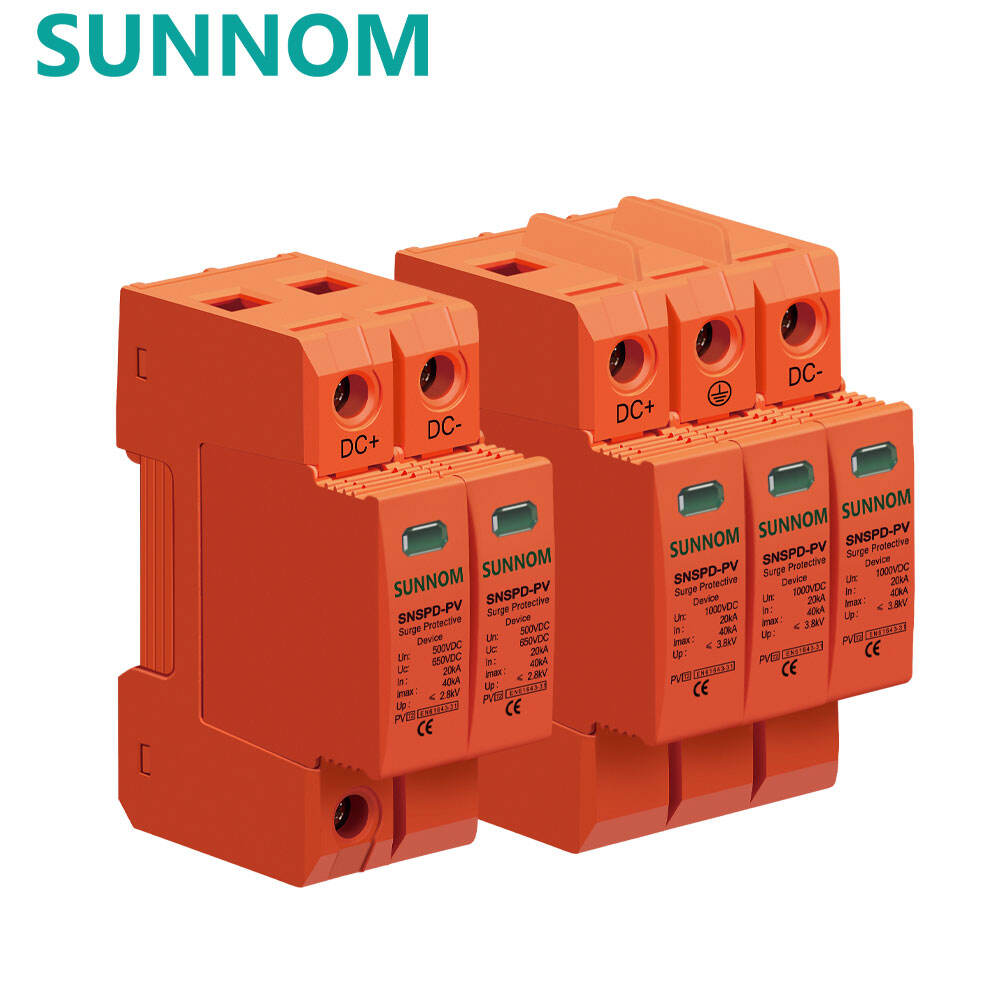

DC surge protectors are available for a wide range of voltage levels, from low-voltage 12V and 24V systems up to high-voltage applications exceeding 1500V. Common voltage ratings include 500V, 600V, 800V, 1000V, and 1500V to accommodate various industrial and renewable energy applications. The selection of appropriate voltage ratings depends on the specific system operating voltage and the required protection margin.

How do DC surge protectors differ from AC surge protectors?

DC surge protectors must handle continuous voltage without the natural zero-crossing points present in AC systems, requiring different protection technologies and coordination strategies. DC systems typically require lower let-through voltages and faster response times due to the continuous nature of the voltage. Additionally, DC surge protectors must be designed to interrupt DC current, which is more challenging than AC current interruption.

What maintenance is required for DC surge protectors?

Regular maintenance includes visual inspection of devices and connections, verification of status indicators, checking for proper grounding connections, and periodic testing of protection device parameters. Most modern DC surge protectors include status indication systems that provide continuous monitoring of device condition. Maintenance intervals typically range from annual to every few years depending on environmental conditions and system criticality.

Can DC surge protectors be retrofitted to existing systems?

Yes, DC surge protectors can typically be retrofitted to existing systems with proper planning and installation. Retrofit installations require careful analysis of existing system architecture, available space for protection devices, and coordination with existing protection equipment. Professional installation ensures proper integration and optimal protection performance while minimizing disruption to existing operations.