Direct current electrical systems require specialized protection components that can handle unique challenges not present in AC systems. DC fuses serve as critical safety devices designed to protect circuits, equipment, and personnel from overcurrent conditions in DC applications. Unlike their AC counterparts, DC fuses must contend with the absence of natural current zero crossing points, making arc extinction significantly more challenging. Understanding the various types of DC fuses and their specific applications is essential for engineers, technicians, and system designers working with photovoltaic systems, battery banks, electric vehicles, and industrial DC power distribution networks.

Understanding DC Fuse Technology and Operating Principles

Fundamental Differences Between AC and DC Protection

The operating environment for DC fuses presents unique challenges that distinguish them from alternating current protection devices. In AC systems, the current naturally crosses zero twice per cycle, providing opportunities for arc extinction and circuit interruption. DC fuses must overcome continuous current flow without these natural interruption points, requiring specialized arc-quenching mechanisms and materials. The steady-state nature of direct current creates sustained arcing conditions that demand innovative fuse designs incorporating sand-filled cartridges, ceramic bodies, and advanced arc-chute technologies.

Modern DC fuses incorporate sophisticated internal structures designed to rapidly extinguish arcs through controlled sand particle interaction and heat dissipation. The fuse element itself must be precisely engineered to provide reliable operation across varying temperature ranges while maintaining consistent time-current characteristics. These protection devices must also accommodate the unique fault behavior of DC systems, where fault currents can rise rapidly and maintain elevated levels without the natural current limitation inherent in AC systems.

Construction Materials and Design Considerations

High-performance DC fuses utilize specialized construction materials optimized for direct current applications. The fuse body typically consists of high-grade ceramic or composite materials capable of withstanding extreme thermal stress during fault conditions. Internal arc-quenching media, commonly high-purity silica sand, provides rapid arc extinction through controlled particle interaction with the plasma channel. The fuse element design varies significantly based on application requirements, incorporating silver, copper, or specialized alloys engineered for specific time-current characteristics.

Terminal construction plays a crucial role in DC fuses performance, with blade-type, bolt-on, and specialized connection methods designed to minimize contact resistance and ensure reliable long-term operation. Environmental considerations drive the selection of housing materials and sealing methods, particularly in outdoor photovoltaic installations where temperature cycling, moisture, and UV exposure present ongoing challenges. Advanced DC fuses incorporate internal pressure relief mechanisms and visual indication systems to provide clear fault indication and safe operation under extreme conditions.

Classification of DC Fuses by Application

Photovoltaic System Protection

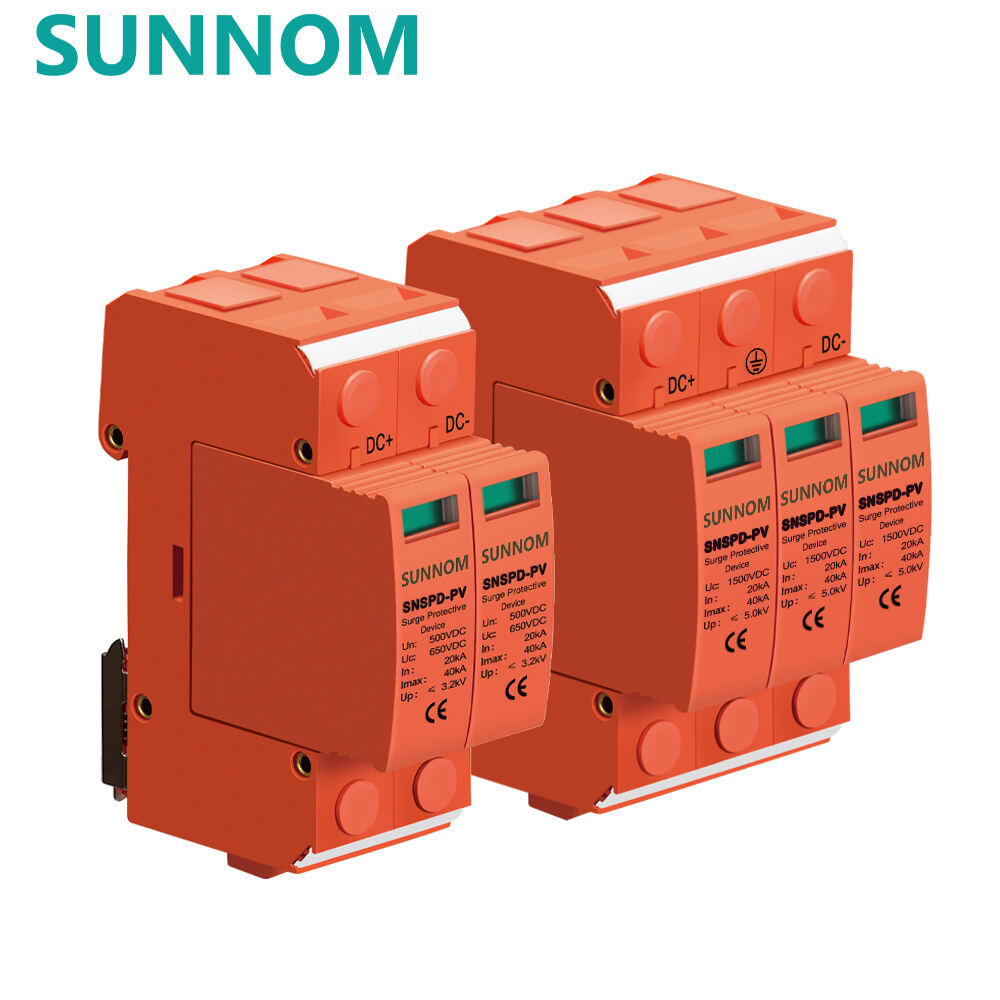

Photovoltaic applications represent one of the largest markets for specialized DC fuses, with unique requirements driven by solar panel characteristics and system configurations. String-level protection requires DC fuses capable of handling the specific fault patterns associated with photovoltaic modules, including reverse current flow, ground faults, and arc flash conditions. These protection devices must operate reliably across the wide temperature ranges encountered in outdoor installations while providing consistent performance throughout their operational lifetime.

Combiner box applications utilize DC fuses designed for parallel string protection, where multiple photovoltaic strings connect to common bus bars. The protection strategy must account for string-to-string fault conditions, reverse current protection, and coordination with upstream protection devices. Modern photovoltaic DC fuses incorporate gPV characteristics specifically developed for solar applications, providing optimized protection while minimizing nuisance tripping caused by normal system transients and environmental conditions.

Battery System Applications

Battery energy storage systems present distinct protection challenges requiring specialized DC fuses engineered for high-energy fault conditions. Battery fault currents can reach extremely high levels due to the low internal impedance of modern battery technologies, demanding protection devices with exceptional interrupting capability. DC fuses used in battery applications must coordinate with battery management systems while providing reliable protection against thermal runaway, cell-level faults, and external short circuits.

Energy storage applications often require DC fuses with enhanced time-current characteristics that allow for normal charging and discharging cycles while providing rapid protection during fault conditions. The integration of these protection devices with smart monitoring systems enables predictive maintenance and system optimization. Battery DC fuses must also accommodate the unique voltage and current profiles associated with different battery chemistries, from lithium-ion to flow batteries and emerging energy storage technologies.

Voltage Classifications and Ratings

Low Voltage DC Systems

Low voltage DC systems, typically operating below 1500VDC, encompass a broad range of applications from telecommunications equipment to industrial control systems. DC fuses designed for these applications must provide reliable protection while accommodating the space constraints and environmental conditions typical of low voltage installations. The protection strategy often emphasizes selective coordination with other protective devices while maintaining cost-effectiveness for high-volume applications.

Automotive and marine applications represent significant segments within low voltage DC fuses markets, where protection devices must withstand vibration, moisture, and temperature extremes while providing consistent performance. These specialized DC fuses often incorporate additional features such as visual indication, remote monitoring capability, and enhanced environmental sealing. The miniaturization trends in electronics drive ongoing development of compact DC fuses suitable for high-density circuit protection applications.

Medium and High Voltage Applications

Medium voltage DC systems, operating between 1500VDC and 35kVDC, require DC fuses with enhanced dielectric strength and arc interruption capability. These applications include industrial electrochemical processes, electric arc furnaces, and high-power motor drives where fault currents can reach substantial levels. The protection devices must coordinate with sophisticated control systems while providing reliable isolation during maintenance operations.

High voltage DC transmission systems represent the most demanding applications for DC fuses technology, where protection devices must handle fault currents in the kiloampere range while maintaining system stability. These specialized DC fuses incorporate advanced arc-quenching technologies and may integrate with intelligent electronic devices for enhanced protection coordination. The development of HVDC systems continues to drive innovation in high voltage DC fuses design, with emphasis on reducing footprint while improving performance characteristics.

Current Rating Categories and Selection Criteria

Standard Current Ratings

DC fuses are available in standardized current ratings ranging from fractional amperes to several thousand amperes, with each rating class designed for specific application requirements. Low current DC fuses, typically below 30 amperes, serve electronic circuit protection where precise overcurrent response and minimal voltage drop are essential. These devices often incorporate specialized fuse elements designed to provide stable time-current characteristics across varying ambient conditions.

Medium current ratings, spanning 30 to 400 amperes, represent the most common category for industrial and renewable energy applications. These DC fuses must balance cost considerations with performance requirements while providing reliable protection across diverse operating conditions. The selection process involves careful consideration of normal operating current, ambient temperature effects, and coordination requirements with upstream and downstream protective devices.

High Current and Specialty Ratings

High current DC fuses, rated above 400 amperes, are engineered for demanding applications where fault current levels can reach extreme values. These protection devices incorporate advanced cooling mechanisms and specialized contact systems to handle the thermal stress associated with high current operation. The physical construction often requires substantial mounting hardware and adequate ventilation to ensure safe operation under normal and fault conditions.

Specialty current ratings address unique application requirements where standard ratings prove inadequate. Custom DC fuses may incorporate non-standard time-current characteristics, environmental specifications, or physical configurations to meet specific system requirements. The development process for specialty DC fuses involves close collaboration between manufacturers and end users to ensure optimal protection performance while maintaining regulatory compliance and safety standards.

Time-Current Characteristics and Performance

Fast-Acting Protection

Fast-acting DC fuses provide rapid response to overcurrent conditions, typically operating within milliseconds of fault initiation. These protection devices are essential for semiconductor circuit protection where component damage can occur rapidly under fault conditions. The time-current characteristics are precisely engineered to provide reliable operation while minimizing let-through energy during fault conditions.

Electronic equipment protection often requires DC fuses with extremely fast response times to prevent damage to sensitive components. The design philosophy emphasizes minimizing arc energy and reducing the impact of fault conditions on adjacent circuits. Modern fast-acting DC fuses incorporate current-limiting technology that restricts fault current magnitude while providing rapid circuit interruption.

Time-Delay Characteristics

Time-delay DC fuses accommodate applications where temporary overcurrent conditions are normal and expected. These devices provide selective coordination with other protective devices while preventing nuisance tripping during motor starting, capacitor charging, or other transient conditions. The time-delay mechanism may utilize thermal elements, spring-loaded triggers, or other technologies to achieve the desired operating characteristics.

Motor protection applications often require DC fuses with specific time-delay characteristics that accommodate starting currents while providing reliable protection against sustained overloads. The coordination with motor thermal protection devices requires careful analysis of system operating conditions and fault scenarios. Time-delay DC fuses must maintain consistent performance across varying ambient temperatures and operating cycles to ensure reliable system protection.

Installation and Application Guidelines

Mounting and Connection Methods

Proper installation of DC fuses requires careful attention to mounting orientation, connection torque, and environmental protection. Many DC fuses incorporate specific mounting requirements to ensure optimal heat dissipation and arc venting during fault conditions. The connection method must provide low resistance joints while accommodating thermal expansion and system vibration throughout the operational lifetime.

Environmental considerations play a crucial role in DC fuses installation, particularly in outdoor applications where temperature cycling, moisture, and contaminant exposure can affect performance. Proper enclosure selection and ventilation design ensure reliable operation while maintaining safety clearances. The installation process should include verification of proper fuse orientation, secure mounting, and adequate access for maintenance and replacement operations.

System Coordination and Protection Strategy

Effective DC fuses application requires comprehensive analysis of system protection coordination to ensure selective operation during fault conditions. The protection strategy must consider the interaction between multiple protection devices, including upstream circuit breakers, downstream contactors, and parallel protection elements. Time-current coordination studies help optimize protection settings while minimizing system disruption during fault conditions.

Load flow analysis and fault current studies provide essential information for DC fuses selection and application. The protection scheme must accommodate system growth, operating mode changes, and maintenance requirements while maintaining reliable protection throughout the system lifecycle. Regular review and updating of protection coordination ensures continued effectiveness as system conditions evolve and new equipment is added.

Maintenance and Testing Procedures

Routine Inspection and Monitoring

Preventive maintenance of DC fuses involves regular visual inspection, connection integrity verification, and performance monitoring to ensure continued reliability. The inspection process should identify signs of overheating, corrosion, or mechanical damage that could compromise protection performance. Thermal imaging provides valuable insight into connection quality and potential developing problems before they result in protection device failure.

Connection torque verification ensures optimal electrical contact throughout the DC fuses operational lifetime. Environmental factors such as temperature cycling and vibration can affect connection integrity over time, making periodic retorquing essential for maintaining low resistance connections. Documentation of inspection results and maintenance activities provides valuable historical data for optimizing maintenance intervals and identifying recurring problems.

Performance Testing and Verification

Periodic testing of DC fuses time-current characteristics verifies continued compliance with protection coordination requirements. Specialized test equipment designed for DC applications enables accurate measurement of fuse response times and current-limiting performance. The testing protocol should simulate actual system operating conditions while providing quantitative data for protection system analysis.

Insulation testing and dielectric strength verification ensure continued electrical integrity of DC fuses installations. High voltage testing protocols must account for the unique characteristics of DC systems while providing meaningful assessment of insulation condition. Test results should be compared with baseline measurements to identify degradation trends and optimize replacement scheduling.

Frequently Asked Questions

What makes DC fuses different from AC fuses in terms of arc interruption?

DC fuses face unique challenges because direct current does not have natural zero crossings like alternating current, making arc extinction much more difficult. AC systems benefit from current naturally crossing zero twice per cycle, providing opportunities for arc interruption. DC fuses must incorporate specialized arc-quenching mechanisms, such as sand-filled cartridges and enhanced cooling systems, to forcibly extinguish the continuous arc that forms during fault conditions. This fundamental difference requires DC fuses to have more robust internal construction and specialized materials to achieve reliable circuit interruption.

How do I select the proper current rating for DC fuses in photovoltaic applications?

Selecting DC fuses for photovoltaic applications requires consideration of the module specifications, string configuration, and environmental conditions. The fuse current rating should typically be 125% to 156% of the maximum series fuse rating specified by the photovoltaic module manufacturer. This ensures protection against reverse current flow while preventing nuisance tripping during normal operation. Additionally, consider ambient temperature effects on both the DC fuses and photovoltaic modules, as high temperatures can affect both current output and fuse characteristics. Consult the National Electrical Code and local regulations for specific requirements in your installation area.

Can standard AC fuses be used in DC applications?

Using standard AC fuses in DC applications is not recommended and can be dangerous due to fundamental differences in operating characteristics. AC fuses are not designed to handle the continuous arcing conditions present in DC systems and may fail to properly interrupt fault currents, leading to equipment damage or safety hazards. DC systems require specialized fuses engineered with appropriate arc-quenching capabilities, voltage ratings, and time-current characteristics specific to direct current applications. Always use fuses specifically rated and tested for DC service to ensure reliable protection and compliance with safety standards.

What factors affect the lifespan and reliability of DC fuses?

The lifespan and reliability of DC fuses depend on several critical factors including ambient temperature, connection quality, environmental conditions, and operating current relative to the rated current. High ambient temperatures accelerate aging of internal components and can affect time-current characteristics. Poor connections create heat buildup and voltage drop that can compromise fuse performance. Environmental factors such as moisture, vibration, and contaminants can cause deterioration of housing materials and internal components. Operating the DC fuses at currents significantly below their rating maximizes lifespan, while frequent operation near rated current or exposure to overcurrent conditions will reduce service life. Regular inspection and maintenance help identify potential issues before they compromise system protection.

Table of Contents

- Understanding DC Fuse Technology and Operating Principles

- Classification of DC Fuses by Application

- Voltage Classifications and Ratings

- Current Rating Categories and Selection Criteria

- Time-Current Characteristics and Performance

- Installation and Application Guidelines

- Maintenance and Testing Procedures

- Frequently Asked Questions